Top Hat Batten Roll Forming Machine

■ Steel Structural Frame Roll Forming Machine for Top Hat Batten

Top Hat Batten also named Top hat channel and Australia top hat batten channel. Top Hat Batten is as an integral part of light steel structure is roll-formed from Hi-Tensile GI steel. With its advantage, it is very popular in the present world market, The Top Hat Batten is widely adopted in Building construction Industry – commercial and residential, they are primarily used to provide lightweight, economical, efficient roofing and cladding support systems for framed structures.

■ Technology Specifications - Steel Structural Top Hat Batten Roll Forming Machine

With more than 20 years experience in this roll forming machinery industry. we have full ability to design the customized roll formers according to client request. After so many years developed, the present Top Hat Batten section roll forming line technology is perfect, including the cost and quality. Various sizes of Omega Profile can be produced by the same line after adjusted by hand wheel or controlled by servo motor. The operation is very simple and quick. The change time and labor fee can be reduced. If the machine investment is enough, This is the proper solution. The servo tracing cutter or stationary cutter can be optional.

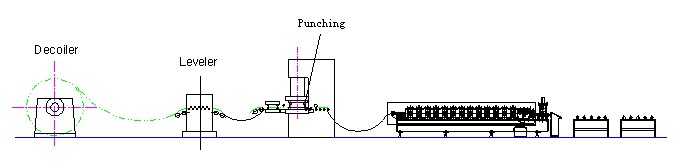

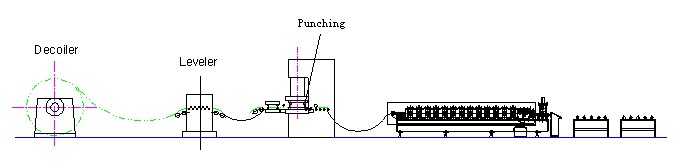

The whole roll form line is consisted of de-coiler, flatting device, holes punching equipments, main roll forming machine, hydraulic cutting part, hydraulic system, PLC control system and run out table, etc.

De-coiling---Coil sheet guiding and feeding---sheets Pre cutting------cut-to-length----Roll forming---- Hydraulic punching holes---cut to length—stacking production

■ Main Parameters- Top Hat Batten Roll Forming Machine

|

Feeding material Thickness:

|

0.3~2.0mm (Q195, Q235)

|

|

Material of roller:

|

Quality moulds steel, polished and coated with chrome, hardness HRC58-62

|

|

Forming Roller Stations:

|

15 Stations, quality casting steel after precision processed.

|

|

Main power:

|

15KW

|

|

Hydraulic station power:

|

5.5KW

|

|

Hydraulic pressure:

|

10-12Mpa

|

|

Leveller

|

4KW

|

|

Control system:

|

PLC Control with touch Screen, Inverter, Encoder are MITSUBISH or Panasonic Brand Japan

|

|

Omega Profile

|

H40-150mm; W 30-90mm

|

|

Product length tolerance

|

2M+/- 1.0mm

|

|

Line speed:

|

10-15m/min (not including cutting material time)

|

|

Size of main machine:

|

11000×1800×1800mm

|

|

Equipment weight:

|

7500kg

|

■ Steel Structural Top hat channel roof batten Machine

- The manual decoiler or hydraulic decoiler can be optional.

- The normal driving system is controlled by chains. Gearing box can be designed according to client request.

- The top hat channel can be customized prepared.

■ Application - Top hat channel roof batten Section

The raw material for the top hat channel is galvanized steel with zinc coating, the thickness is 0.3~2.0mm

This profile also named Australia top hat batten channel. Mostly it is used for ceiling or roof system. The advantage: is rust-proof, fire-proof and easy to install. It is suitable for all size of the hotel, airport, office buildings, shopping malls and other public, home decoration places.

TAG: Steel Structural Profile machine, Top hat Roll Forming Machine, Top hat channel, roof batten, Australia top hat batten

Last:Roof Batten Roll Forming Machine

Next:C-Z Purlin Roll Forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,