■ Duct Flange rollformer for the manufacture of air condition duct fittings

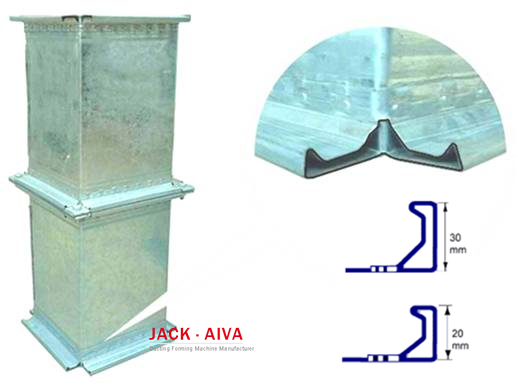

This GDF Duct flange Rollforming machine was specially designed to manufacture HVAC flanges of 20 and 30 mm size for medium and large producers of square HVAC duct. GDF integral flange is widely applied in Europe as a kind of quick installation duct flange. It shares common advantages with TDF flange well seal, free of jointing and rivet. GDF flange is integral with duct, with 4 bolts and special duct corner and clamp.

The GDF flange machine is designed according Cantilever Roll Former, with two sets of forming rollers installed both side, one machine can produce two sizes GDF flanges, so that the Change of 20-30 or 30-20 flange produced is also very easy and quick.

The GDF Flange production can be allowed to roll form down to 400 mm long without trolley and 200 mm with trolley. It can accept short pieces without the need for clamps. The Minimum length is 250mm.

■ Technical parameters- GDF Duct Flange Roll Forming Machine

|

Raw material:

|

GI steel strip, carbon steel strip, etc

|

|

Flange Heights

|

20mm / 30mm

|

|

Forming roller

|

20sets

|

|

Raw material thickness range (mm):

|

0.6 - 1.2mm

|

|

Forming roller station quantity:

|

About 25 Stations

|

|

Motor power

|

5.5kw, AC380v, 50HZ

|

|

Weight (KG):

|

About 2000

|

|

Line Dimension (L*W*H)mm:

|

5250x800x1600

|

|

TDC flange profile:

|

(according to the client’s sample or drawings)

|

■ GDF Duct Flange, CGF1 flange

The following samples is produced by the flange Rollforms similar with CGF1 flange duct system with rotary metal stitching. The last two stations on the rollforming section perform the stitching operation. The whole line has 20 stations forming rollers, 5.5kw. With our more than twenty years experience, the flange profiles from the line is perfect and tighten.

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,