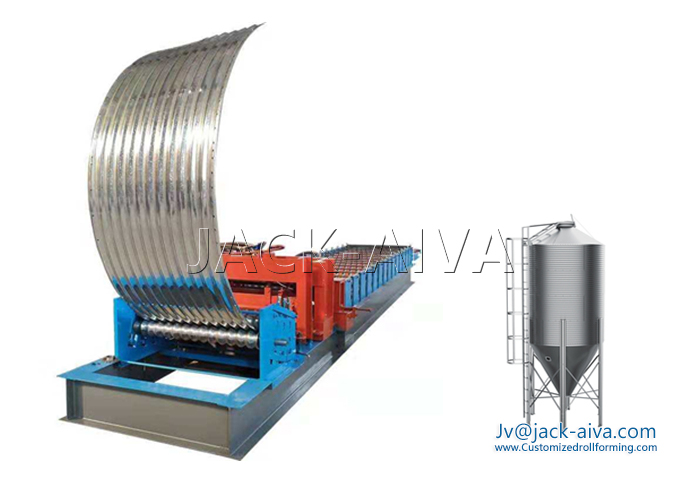

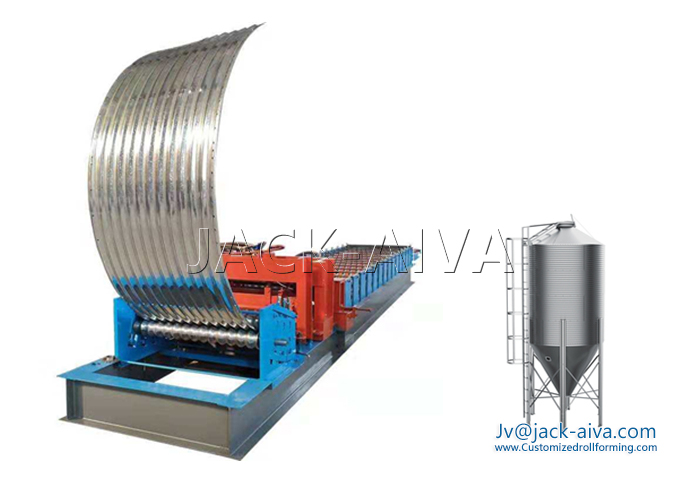

Storage Tank Corrugated Sheet Full Auto Line 1.6mm

■ Roll Forming Line for production Storage tank corrugated sheet or wall by 1.6mm thickness

Storage tank corrugated sheet roll forming machine is consisted un-coiler, entrance, main roll former for processing corrugated steel sheets, servo control feeder and hydraulic punching holes device, three roller bending machine. The forming machines are specifically designed to roll forming corrugated sheets of galvanized steel up to 1.6mm thick. it is for stroage tank walls. The profile can be custom made according to request.

The advantage of the cutter after bending is to get more perfect shape at the corrugate sheets both ends.

■ Production Technology specifications

Corrugated Sheet Roll Forming line consists of Uncoil device, Roll forming machine, Hydraulic automatic cut-off, Products run-out table, PLC automatic control system, etc.

Also this roll forming line can roll form pre-cut flat sheets. Considered the better corrugated sheets, the coil as raw material is recommended.

■ Corrugated sheet roll forming machine technology Flow

Manual De-coiler (5Ton) --- feeder + leveler + Roll forming Machine ---- Servo Tracing punching (Side holes + Cross holes) --- hydraulic cutter (Stop-cut) ------ corrugated sheet bending -- finished products

■ Production line Main Parameters- Storage tank corrugated sheet

|

Item |

Content |

|

Raw material |

- Thickness 1.0-1.6mm;

- Coil width is according to client profile

- Yield Strength ≤300MPa |

|

De-coiler |

- Capacity: 5Tons

- Inner extending cantilever style, manual control,

- Coil ID: 470mm-510mm; Coil OD:1300mm |

|

Main roll former |

- Roll station:20 stations

- Material of main shaft ¢90mm, 45#, treating

- Forming rollers GCR15, quenching, hardness HRC58-62º, chrome plated

- Driving model: By chain (gearing box driving system is optional)

Main motor power: 22kw

Working speed: 0-15m/min, not including punching and cutting |

|

Servo Tracing punching |

Side holes + Cross holes; 5.5KW (+ accumulator ) / 25Mpa |

|

Bending device |

- Corrugated steel sheet 3 roller Bending; UP shaft 1 pc; Down shaft 2pcs

- Power 5.5kw

- Roller material GCR15

- Driving model: By Double line chain |

|

Cutter |

- Stationary Hydraulic Cutter

- Cr12MoV, quenching and hardness 58°-62° |

|

Controlling system: |

PLC & Touch screen |

|

Total weight: |

About11,000kg |

|

Size |

11500×1500×1200mm |

■ Application sample: Grain silos tank

TAG: Storage Tank Corrugated Sheet Roll Forming Machine, Storage Tank corrugated wall

Last:No

Next:Steel Corrugated Wall Sheet Making Machine 3mm

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,