K-Span Arched Panel Machine,

■ K-Span Arched Panel MIC-120, MIC 240

The steel structure building with K-SPAN arched panels is a new form of construction. K-span arched panels are seamed together to form an economical and watertight steel structure. The final shape and strength of the materials used cancels the need for columns, beams, or any other type of interior support. All of the panel-to-panel connections are joined using an electric automatic seaming machine. Because of this, there are no nuts, bolts, or any other type of fastener to slow down construction or create leaks. Buildings can be built quickly and efficiently.

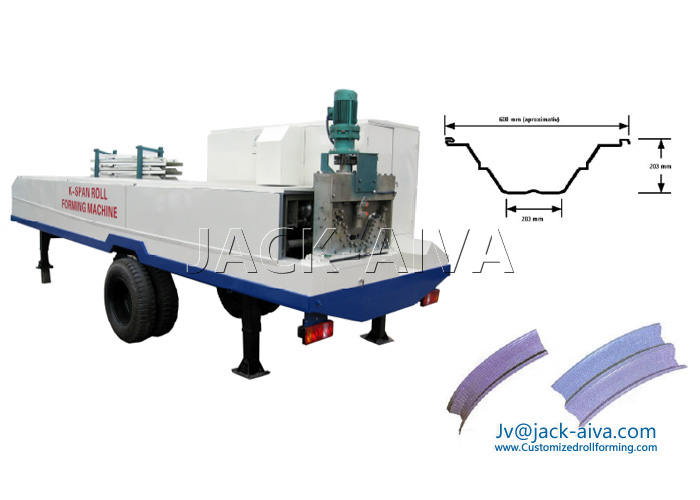

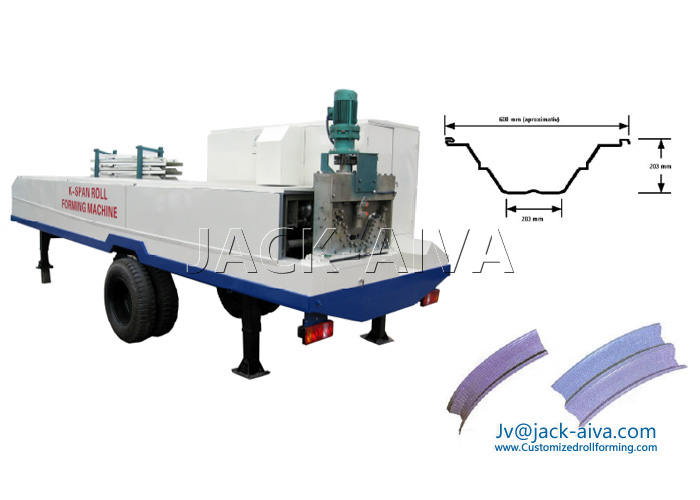

■ Roll Forming Machine Trailer-Mounted for production K-Span Arched Panel MIC-120, MIC 240

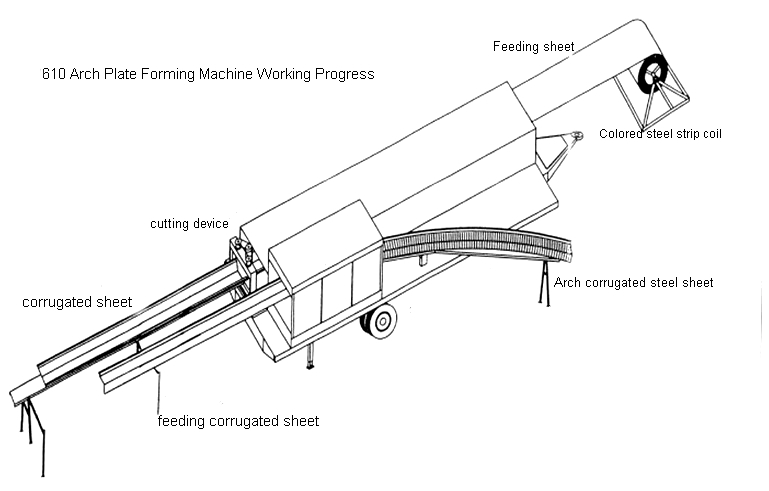

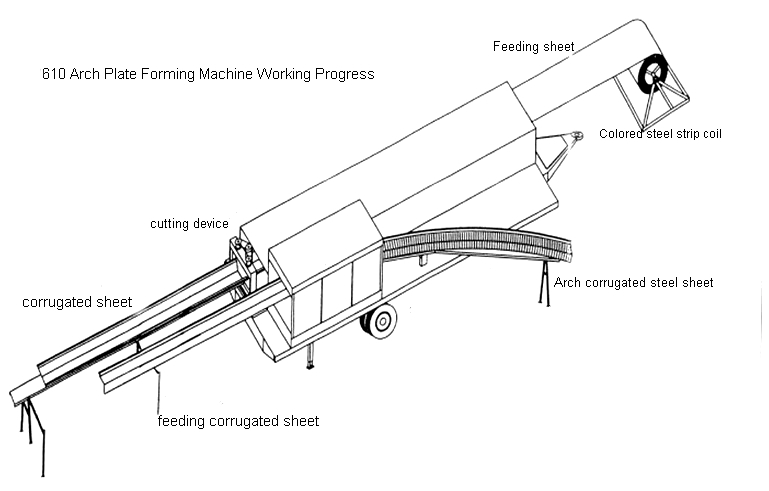

K-Span Curving Roof production line is consisted of straight roof panel Profile roll forming machine, arc panel curving machine and seam locking machine. These components are all installed on an trailer. So The K-span arc panel production machines can be moved to working site. Also the Generator can be set on the trailer as necessary power supplier. The steel coil thickness range processed by this line can be from 0.5 to 1.5mm. The cut-to-length is auto controlled.

The following is the technology drawing about the K-span arched panel production machine.

■ Main Parameters- MIC-120K & MIC 240-Span Arched Panel Production Machine

|

Item

|

Content

|

|

Roll Formed Profile Type:

|

K-Span metal Roof panel 914-610

|

|

Raw material width:

|

According MIC-120, MIC 240 Profile

|

|

Raw material thickness:

|

0.6-1.5mm

|

|

Max k-span width

|

24m

|

|

Line speed:

|

Straight sheet: 15m/min

|

|

Arch sheet: 13m/min

|

|

Sewing: 16m/min

|

|

Rollers station:

|

13 sets

|

|

Material of roller:

|

45# forge steel

|

|

Material of main shaft:

|

Ф85mm

|

|

Main power:

|

15.5KW

|

|

Material of cutting blade:

|

CR12, Quenched

|

|

Min. Radius:

|

R=12000mm

|

|

Bending power:

|

3.0KW+1.1KW+1.1KW

|

|

Total Weight:

|

10000kg

|

|

Control system:

|

Electrical control

|

|

Total Line size:

|

8900×2200×2400mm

|

|

Machine components included

|

K Span Straight Roof Panel Roll Forming Machine

Arc Panel Curving Machine

Automatic Locking Machine / Snap locker

|

■ K-Span Arched Panel profile MIC-120 & MIC-240

Color steel sheet arched roof is cold roll formed with a thickness of 0.6 ~ 1.5mm, into an straight slot plate, U channel shape, then curved into an long k-span arched panel, mechanically engage the hemming to form an integral arched roof structure. This advanced construction technology was developed by the American MIC Industrial Company in the 1980s. It is a revolutionary product with a unique idea. It can build 3 ~ 36m width self-supporting arc roof with steel sheet thickness 0.6 ~ 1.5. K-span Arc panel MIC-120 is an U shape style profile, the raw material can be 600mm or 914mm, the normal Maximum span is 24m; Another style arc panel is MIC-240, it is the bigger one, the normal span can be 36mm.

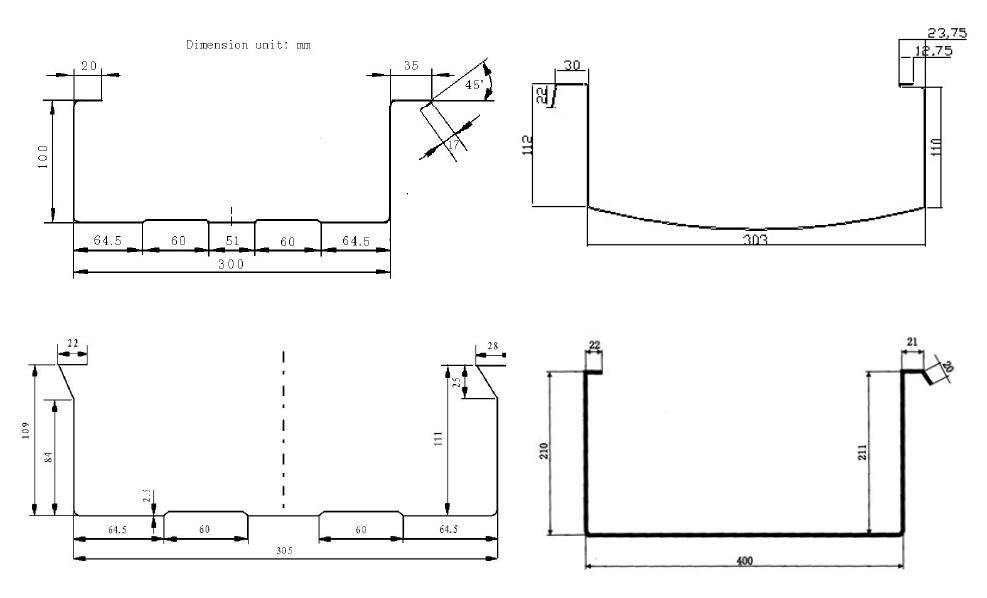

■ MIC120 K-Span Arch Sheet Profile

■ K-Span Arch Sheet Profile MIC120

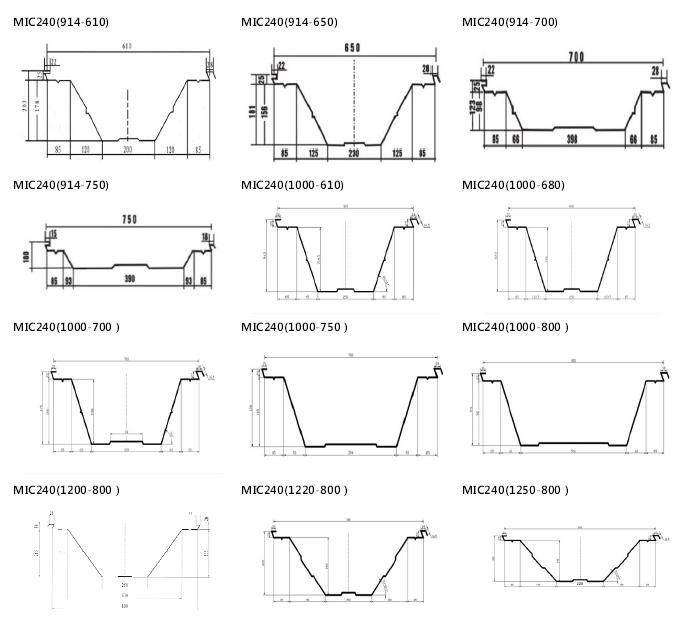

There still have the other style K-span arched panels in the marked, just provided in different section on the K-span roof panel, We can manufacture as per customer provided drawings or real objects of sectional materials, customization is welcome. The following is some profiles as reference.

■ MIC120 K-Span Arch Sheet Applications

For further details about MIC-120 & MIC 240 Machine, please contact with us!

TAG: K-Span roll forming machine, K-Span Arched Panel Machine, MIC-120

Last:K-Span Arched Panel Machine

Next:Corrugated sheet rolling machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,