Large Span Arched Panel Machine

■ Roll Forming Machine for production Large span Arched Panel

The steel structure building with large Span arch panels is a new form of construction. The straight channel profiles and the arched panels can be seamed together to form an economical and watertight steel structure. The final shape and strength of the materials used cancels the need for columns, beams, or any other type of interior support. All of the panel-to-panel connections are joined by nuts, bolts, to slow down construction or create leaks. Buildings can be built quickly and efficiently.

■ Large Span Arc Panel Roll Forming Machine Technology Specifications

Large span Roof panel production line is consisted of straight roof panel Profile roll forming machine, arc panel curving machine and seam locking machine. The following is the large span arched panel production machine technology flow drawing.

Hydraulic De-coiling (10tons) --- Flatting device + Feeder by servo motor control ---- Hydraulic punching with holes punching moulds --- Roll forming--- Cutting ---- Run-out table

■ Main Parameters- MIC-240K-Span Arched Panel Production Machine

|

Item |

Content |

|

Roll Formed Profile Type: |

Large Span metal Roof panel |

|

Raw material width: |

According panel Profile |

|

Raw material thickness: |

0.8-1.8mm |

|

Max k-span width |

30m |

|

Line speed |

Straight sheet: 15m/min |

|

Arched sheet: 3-5m/min |

|

Rollers station: |

12sets |

|

Material of roller: |

45# forge steel |

|

Material of main shaft: |

Ф85mm |

|

Main power: |

7.5KW |

|

Material of cutting blade: |

CR12, Quenched |

|

Max bending length |

2.8m |

|

Bending mode and direction |

2wave/stroke; down direction |

|

Max bending angle |

120° |

|

Control system: |

PLC and touch screen control |

|

Bending machine Sizes |

3000×1400×1400mm |

|

Roll Forming Line size |

8900×2200×2400mm |

|

Machine components included |

Large Span Straight panel Roll Forming Machine

Arc Panel Curving Machine |

■ Advantages of the Large span arched panel building

There has report showed the costs 40-60% less than labor-intensive conventional construction or prefabricated buildings. The state-of-the-art technology lowers cost by reducing the crew and by eliminating your dependency on architects or engineers. With the seaming machine, there is no need for nuts, bolts or screws. This feasible solution allows you to manufacture a building in as little as a single day, saving valuable time and money.

The K-span arched panels allows you to build structures to your unique specifications. Clear span building widths can be small or large. Building lengths and the ability to later expand a building are unlimited, provides you with capability to create self-supporting ground-to-ground panels with gable, double and single radius designs. Various colors of steel can also be used to enhance the appearance of your buildings.

The constructs durable, virtually maintenance-free buildings, because they are watertight, rust-free and fireproof. Buildings with K-Span arched panels have been tested for severe weather conditions and can withstand typhoons, earthquakes, harsh winds and heavy snow.

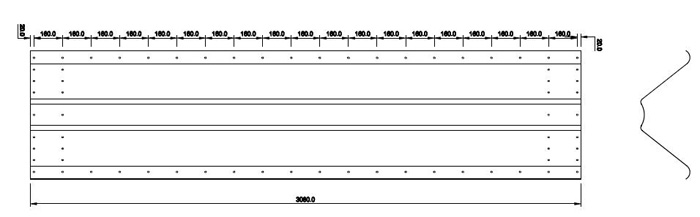

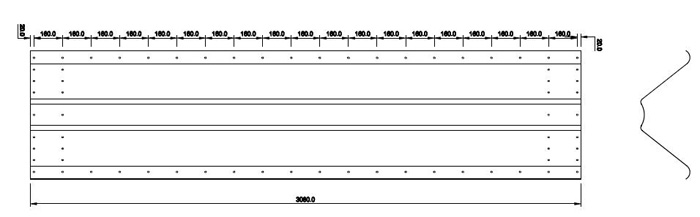

■ Large Span Arch Sheet Profile

■ Large Span Arch Sheet Applications

For further details about the large span panel Machine, please contact with us!

TAG: Large Span arc panel machine, Arc panel making Machine, large Span Arched Panel Machine, Roll Forming Machine

Last:3D Roof Tile Roll forming Machine

Next:K-Span Arched Panel Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,