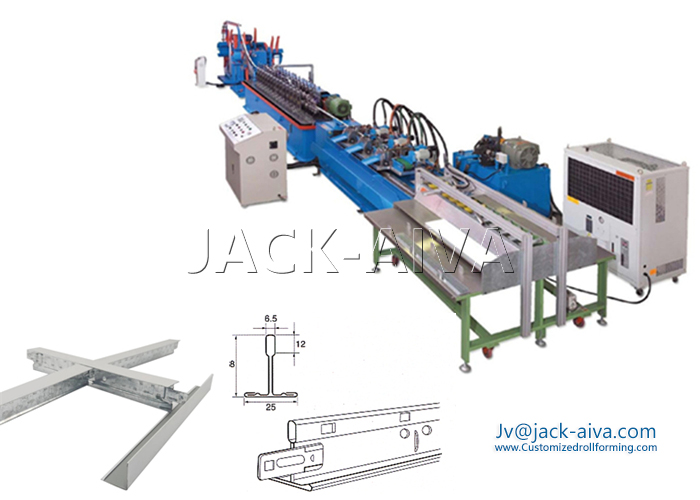

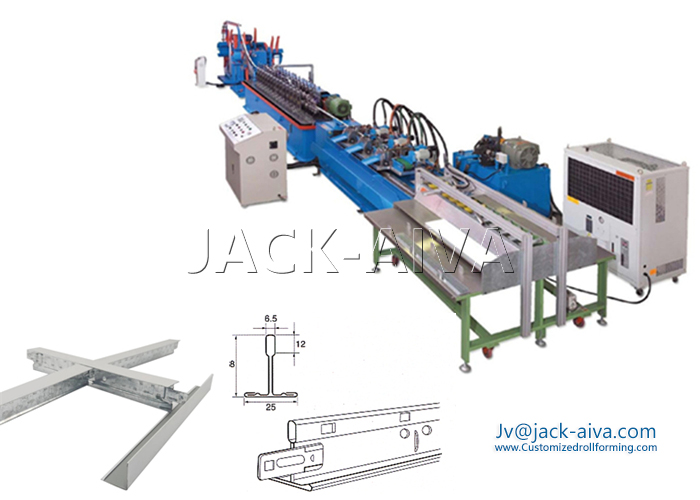

Main T Grid Roll Forming Machine

■ Brief Introduction- Ceiling T Grids of Suspension System

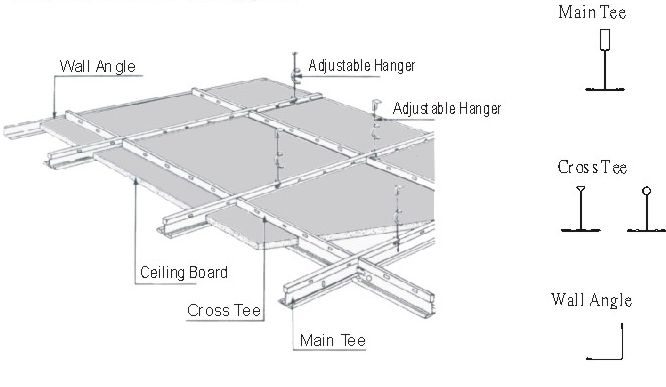

Cold Roll Forming Machines for production metal Ceiling T grid system profiles, We provide you the fully automatic machine with in-line punching of T-bars in the various custom models and sizes. The ceiling T Grids suspender system main components are consisted of main T-Bar Machine, cross T-Bar Machine and Wall L Angle.

There have three auto roll forming lines for production the t bar ceiling system, the man t bar roll forming machine, cross t bar roll forming machine and L angle roll forming machine.

■ Roll Forming Line specifications - Main T Grid Roll Forming Machine

We can supply the Complete roll forming lines for the production of T-bars in the various models and sizes, Flexibility in the choice of the sizes, Possibility to produce also complex profiles.

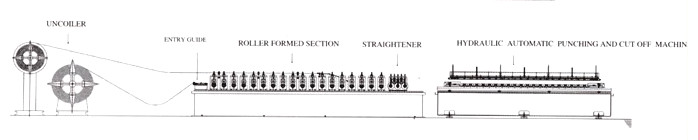

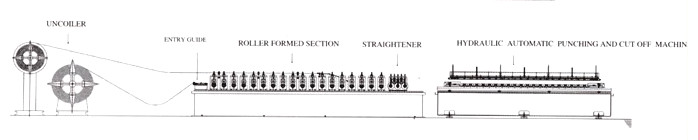

The full automatic Main T-bar (Tee) Cold Roll Forming Machine is consisted of Single or Dual Head Type de-coiler, Roll forming main machine, Hydraulic, Automatic Punching and cut-off Device, run-out table, PLC Automatic Control Cabinet. The main T grid can be finished by our auto line at one time.

■ Machine Parameters- Main T grid Cold Roll Forming Machine

|

Forming Roller Stations:

|

Around 18 Stations

|

|

Forming Roller shaft:

|

φ36mm

|

|

Forming rollers

|

C12MOV, Quenching, hardness HRC62-64º

|

|

Forming Speed:

|

12 meters / min

|

|

Main motor:

|

5.5kw

|

|

Sheet Thickness:

|

0.3 to 0.35 mm

|

|

Cutting mode:

|

Hydraulic automatic punching and cutting machine

|

|

Hydraulic Punching system

|

Dies of (3 in one) for Main T

Dies of notching both side for Main T

|

■ Main T grid Profile

Main T grid: METAL THICKNESS: 0.28mm; LENGTH: 3,600mm

Main T bar production machine Accessories:

Holes and ends punching Dies is including this roll forming machine. These moulds can be custom designed according client drawing or sample.

■ Main T grid Application - Ceiling T Grids of Suspension System

Ceiling T Grids, A system of Ceiling Suspension System members, The ceiling T Bar Lay in Grid System consists of only one tile per module with both the main runner and cross runner exposed. All edges of the tile are supported by the exposed T bars reducing the chance of visible damage after accessing the ceiling cavity. It is the ideal solution for suburban offices, hospitals and schools offering a simple system that is easy to maintain and install.

■ T-Runner Suspended exposed ceiling grids

The Tee bar size is according to clients’ request. You are welcome to contact with us for the further details!

Last:Drywall Angle Roll forming Machine

Next:Cross T Grid Roll Forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,