Lighting Fixture Roll Forming Line

■ Cold Metal Roll Forming Line for Production Lighting Industry

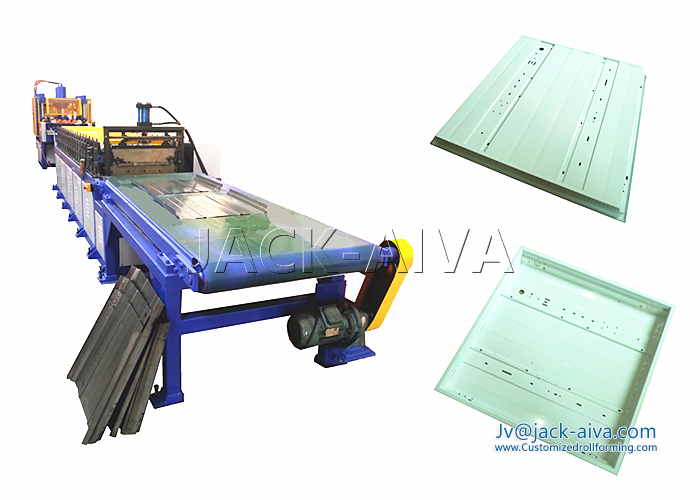

Our Lighting Fixture production line is an expert machine specialized in lighting fixture industry. The light fixture profile roll forming Line is consisted uncoiler, leveling device, Hydraulic punching & Notching device, Main roll forming machine, Hydraulic cutter, and run out table, etc.

We design the roll forming line that achieve critical cosmetic surfaces and production efficiency can be met your requirements. In-line precision punching and notching make the designs assembly-ready. See us for manufacturing equipment to produce everything from under-counter lighting to commercial and industrial florescent light fixture components.

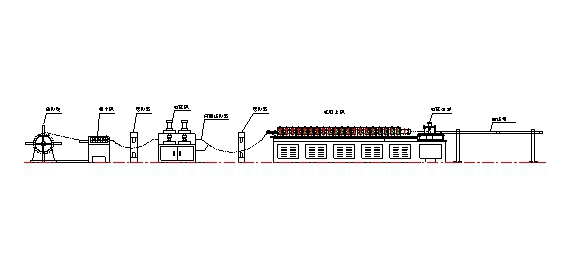

Lighting Fixture production Line flow

■ Main Parameters - light fixtures Roll forming Line

|

Line structure |

Portal-type frame style: 45# steel |

|

Forming Roller Stations: |

20 Stations |

|

Forming Roller shaft: |

¢57mm, 40Cr, quenching, treating |

|

Forming rollers |

CR12MOV, quenching, hardness HRC58-60º |

|

Forming Speed: |

0-8m / min |

|

Main motor: |

11kw |

|

Hydraulic station motor |

15kw |

|

Suitable raw material: |

Q235A galvanized steel sheet |

|

Driving mode: |

Chain |

|

Cutting mode: |

automatic punching cutting style |

|

Blade material: |

CR12MOV, quenching and treating |

|

Control mode |

PLC |

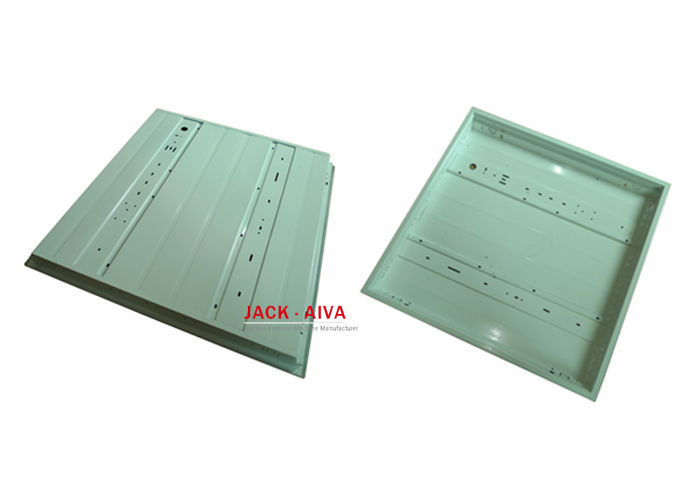

■ Lighting Fixtures profile

The Lighting fixture manufacturing roll forming Line and our related production equipment produce fluorescent channels, troffer, reflectors, louvers, blades, and covers from gloss- painted steel and highly polished anodized aluminum.

The main process of light fixtures is completed by the Roll forming machine, both ends process by separate hydraulic press machine. The following is the profile, the custom lighting fixtures profile is welcome!

TAG: Lighting Fixture Roll Forming Production Line, Lighting Fixtures, Roll Forming Machine, Lighting Fixture, light fixtures Roll Forming machine

Last:Lighting Fixture Roll Forming Machine

Next:No

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,